Leifeld

LEIFELD

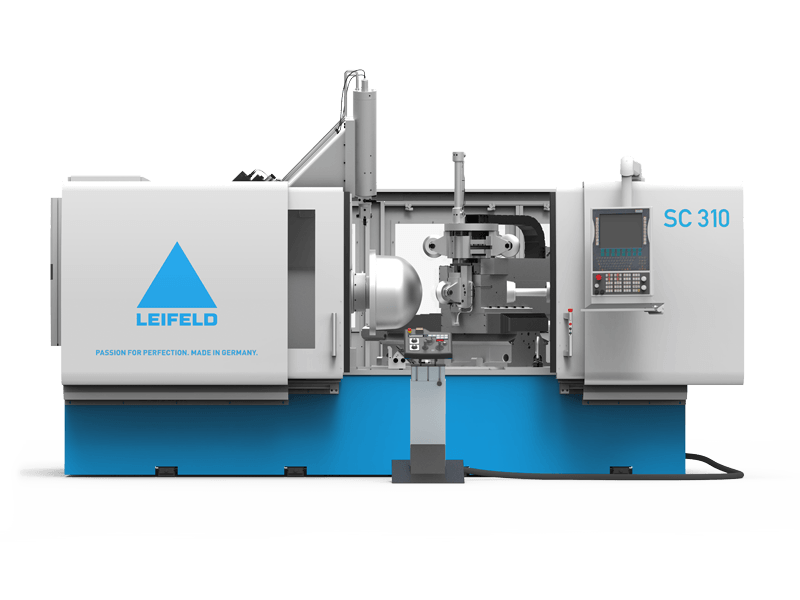

Precision Spinning Machine

Leifeld is the global leader in the development and manufacturing of machine tools for chipless metal forming.

We have produced over 6,000 machines in Germany to date, for both national and international customers. 125 years of accumulated experience has been passed on down the generations, guaranteeing the highest of quality standards made in Germany.

More than 6.000 machines delivered into more than 60 countries are the proof for the outstanding competency and know how at Leifeld.

Features

THE UNIVERSAL ONE – METAL SPINNING TECHNOLOGY WITH UNIVERSAL APPLICATION AND HIGH PRECISION AND RELIABILITY

The SC-series offers high-performance metal spinning machine tools that excel at stability, flexibility and ease-of-use. The proven machine concept offers stable design with optimal access to the working area, making it the ideal basis for efficient production of small, medium and large lot sizes of most diverse end products.

ECONOMY

Material savings, the opportunity to make almost any form changes at low tool costs and quickly, all combine to make spinning the most competitive alternative to other procedures such as deep drawing.

FLEXIBILITY

For the greatest part, the tools (pressure rollers) are not dependant on the geometry of the workpiece. As a result, it is possible to change the geometries in almost any workpiece area simply by making a small change in the programme. Only the spinning form is workpiece-specific. Their flexibility suits our spinning machines for the production of a smaller batch sizes and prototype production. The decisive factor is the low tool and spinning form costs.

EFFICIENCY

The high level of strain hardening enables the use of more affordable materials whilst guaranteeing high levels of stability of the finished part and the required increased consistency. This produces extensive potential for material and weight savings.

Leifeld Metal Spinning

Metal Spinning allows the manufacturing of seamless metal parts succh as e.g. container floors, reflectors, wheel rims, gas cylinders or separator parts. Through this chipless metal forming process, a high shape and dimensional accuracy is achieved which makes post-processing of workpieces obsolete in the vast majority of cases.

PRODUCTS